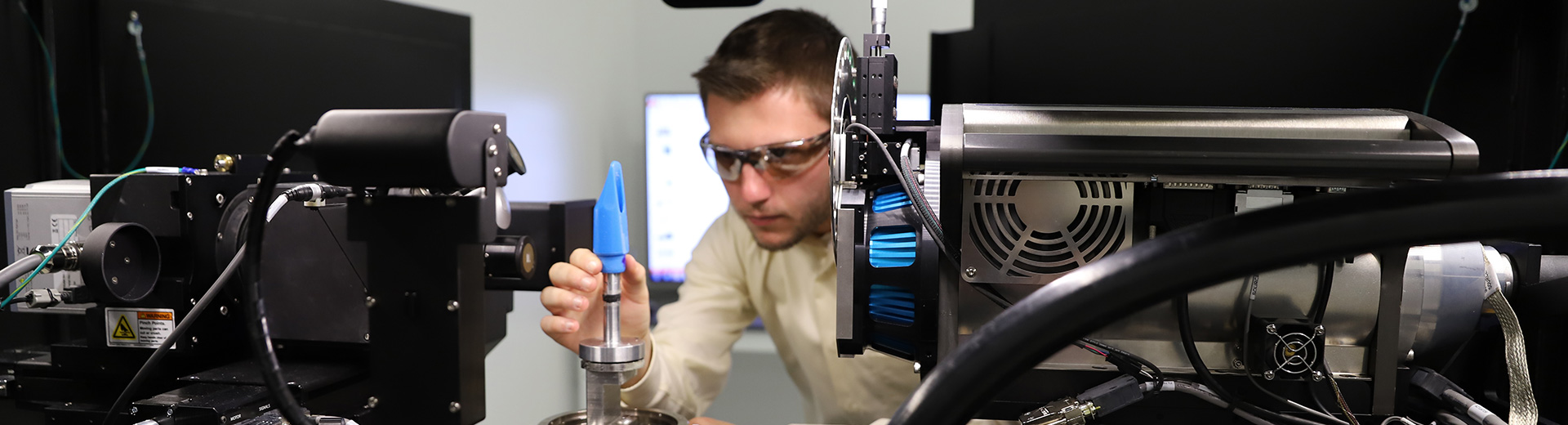

High Tech Equipment

IPB equipment is available for collaborative research between UConn researchers and students and industry partners, small, mid-sized and large companies, as well as entrepreneurs. For further information and other inquiries, please contact the respective research center director.

Filter

Thermo Fisher Scientific Center for Advanced Microscopy and Materials Analysis (CAMMA)

CENTER: CAMMA

Strata 400S Dual Beam

- Dual beam systems uses electron beam for imaging and gallium ions for imaging and precise micromachining

- High resolution imaging down to the nanometer level

CENTER: CAMMA

Helios 460F1 Dual Beam

- Dual beam system uses electron beam for imaging and gallium ions for imaging and precise micromachining

- High resolution imaging down to the sub-nanometer level

CENTER: CAMMA

Helios PFIB Dual Beam

- Dual beam system uses electron beam for imaging and xenon ions for imaging and precise micromachining

- Large volume 3D characterization

CENTER: CAMMA

Aspex Explorer VP SEM

- Easy operation in high and low vacuum mode facilitates imaging of any material

- Auto-mode particle counting, measuring, and chemical identification requires no user input once initiated

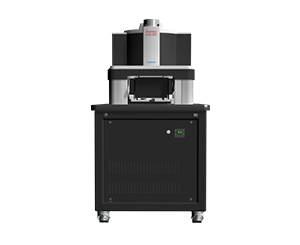

CENTER: CAMMA

Teneo LV SEM

- Unique detection system provides high contrast for a wide range of samples

- Low vacuum mode allows analysis of insulating samples with no conductive coating

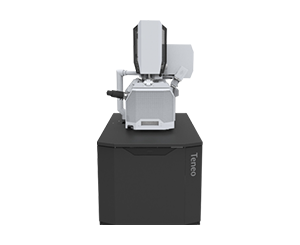

CENTER: CAMMA

Verios 460L SEM

- High resolution imaging to the nanoscale with multiple detectors for topographic and compositional material information

- High flexibility in loading samples gives additional options for analyses

CENTER: CAMMA

Tecnai T-12 TEM

- Nanometer level imaging and elemental analysis

- Variable accelerating voltage can be customized to suit sample sensitivity

CENTER: CAMMA

Talos 200 S/TEM

- Atomic resolution imaging and elemental analysis

- Customized fittings available to perform in situ dynamic experiments in real time

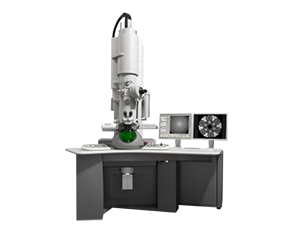

CENTER: CAMMA

Titan Themis ACEM

- Single atom resolution imaging and elemental analysis

- Spherical aberration corrected for the highest spatial resolution

Pratt & Whitney Additive Manufacturing Center (PW AMC)

CENTER: PW AMC

Wire Electrical Discharge Machining

CNC controlled. Removes parts from the build plate and performs finish machining

CENTER: PW AMC

MRF Arc Melter

MRF arc-melter with single-crystal pulling option, gas purification, oxygen monitoring, vacuum casting

CENTER: PW AMC

Furnace Rheometer

Viscosity measurements of liquid metals and alloys

CENTER: PW AMC

LECO CS 844

Carbon-sulfur impurity analyzer

CENTER: PW AMC

LECO ONH 836

Oxygen-nitrogen-hydrogen impurity analyzer

CENTER: PW AMC

TA Instruments ODP 868

Optical determination of thermal expansion, melting, and sample flexure to 1,600 degrees celsius

CENTER: PW AMC

TA Instruments EM DLF1600/2800 (Laser Flash)

DLF 1600 with 2800 environmental module for thermal diffusivity measurements

CENTER: PW AMC

Camsizer XT

Powder size and shape distribution analysis

CENTER: PW AMC

3DSystems ProX300

Laser-based metal additive manufacturing machine

CENTER: PW AMC

EOS M270

EOS laser sintering system for the production of tooling inserts, prototype parts and end products directly in metal

CENTER: PW AMC

Arcam Electron Beam Melting A2X Machine

Capable of manufacturing large, complex metal parts at high temperatures

CENTER: PW AMC

Gleeble 3500

Gleeble 3500 with high-temperature mobile conversion unit and HydraWedge mobile conversion unit

CENTER: PW AMC

Pegasus DSC

Differential scanning calorimeter designed for determination of thermodynamic properties of ceramics and metallic high-performance materials.

CENTER: PW AMC

Agilent ICP 770

Chemical analysis of inorganic materials

CENTER: PW AMC

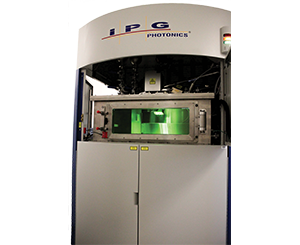

IPG Laser Printer SLM

Laser-based metal additive manufacturing machine with vacuum, pre-heating, fully open architecture and configurable hardware options.

Reverse Engineering Fabrication & Non-Destructive Evaluation (REFINE)

CENTER: REFINE

Smartzoom 5

- Automated digital microscope for QC and failure analysis

- 2D and 3D imaging and measurement

CENTER: REFINE

Smartproof 5

- Laser scanning confocal microscope for surface topography measurements

- Allows for 10nm vertical resolution

CENTER: REFINE

Micrion Vectra 986+

- Focused ion beam instrument with gas-assisted etching and beam-induced deposition

- Enables IC circuit edit for debugging microchip designs and accessing internal data of security and encryption microcontrollers

CENTER: REFINE

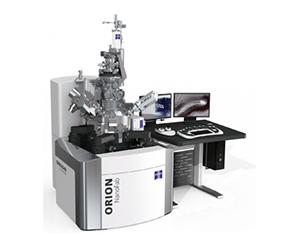

Orion Nanofab

- Focus ion beam (FIB) microscope with helium and neon beams

- Imaging resolution down to 5 angstroms and sub-10nm material removal

CENTER: REFINE

Crossbeam 340 w/ Laser

- Scanning electron microscope with integrated gallium ion beam allowing nanometer precision material removal

- Capable of 3D nanotomography, nanofabrication, and precise analytical analysis

CENTER: REFINE

Xradia MicroCT 400

- X-ray computer tomography system

- Complements Xradia Versa with lower energy limit, best suited for less dense materials

CENTER: REFINE

Xradia Versa 520

- X-ray computed tomography with submicron resolution

- Produces 3D data non-destructively allowing unparalleled insight into internal material structure and sample analysis

X-Ray Lab

CENTER: X-Ray Lab

ZSX Primus IV XRF Spectrometer

- Quick analysis of the major and minor elements (ppm)

- Qualitative and quantitative determination from boron to uranium

- Mapping and multi-point measurements

CENTER: X-Ray Lab

SmartLab X-ray Diffraction System

- Crystal structure of thin films, powders, and bulks

- High power rotating anode and 2D detector

- 10+ modes of analysis, i.e. GIXRD, XRR, residual stress, in-situ, and more

Proof of Concept Center (POCC)

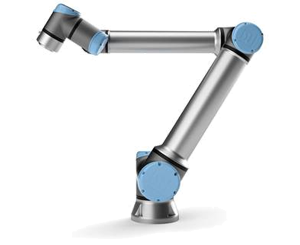

CENTER: POCC

Universal Robot UR10e

Collaborative Robot 6 axis robotic arm with Robitiq Gripper

CENTER: POCC

OMAX Protomax Waterjet

Cuts virtually any material up to 1 inch thick. 30 ksi pump pressure drives the fastest and most efficient cutting for its size

CENTER: POCC

Universal Laser Systems ILS 12.150D

Dual laser platform capable of cutting and etching of many materials

CENTER: POCC

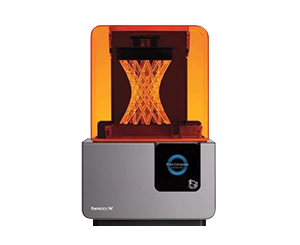

Formlabs Form 2

SLA Benchtop 3D printer that uses a laser to cure solid isotropic parts from liquid photopolymer resin

CENTER: POCC

Stratasys Design F370

Fusion deposition modeling 3D printer capable of creating complex, functional parts in ABS, PLA, ASA, and PC for prototyping, manufacturing jigs, fixtures and tools

CENTER: POCC

Stratasys Connex350

Full color multi-material 3D printer capable of jetting multiple assembly of parts at 16 micron resolution

CENTER: POCC

Haas CNC Lathe

For turning of small parts in metal, plastics, foam, and composites

CENTER: POCC

Haas CNC Mill

3-axis machining center with tool changer. Capable of cutting metals, plastics, foams, and composites

CENTER: POCC

3D Scanner and CMM probe

High resolution, large envelope 3D Scan Arm to output 3D scan models to popular design software like SolidWorks, Creo, 3DS Max, Rhino, and more.

Eversource Energy Center (EEC)

CENTER: EEC

RTDS Testbed

Advanced Real-Time Digital Simulator (RTDS) testbed consisting of three NovaCor Chassis features IBM’s POWER8TM processor running at 3.5 GHz that can conduct dynamic simulations for large-scale power systems with thousands of nodes in small timesteps in real time.