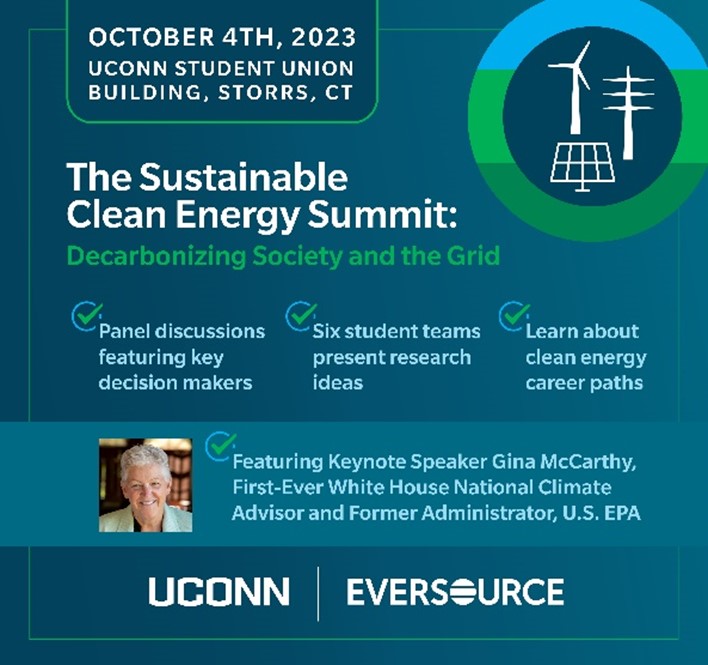

Registration is now open for The Sustainable Clean Energy Summit: Decarbonizing Society and the Grid on October 4, 2023.

Co-hosted by the University of Connecticut and Eversource, the summit will take place at UConn, Storrs and will bring together academic, utility, industry, municipal and legislative experts to discuss the shifting energy landscape and will feature final presentations from six student-led research teams as part of the Eversource-sponsored Clean Energy and Sustainability Innovation Program (CESIP). As part of this program, students are researching possible solutions (technical, social, and political) to address different aspects of the grand challenge of decarbonization at the local (UConn campuses), state and regional (New England) levels.

The student teams will be presenting their work at the summit. Based on their presentations and the future potential of their work, a winning team will be selected for funding. It is our hope that highlighting the important work of these students on real challenges will open the door for engaging conversations throughout the summit. We anticipate many students will attend.

The summit will open with the keynote speaker Gina McCarthy, White House National Climate Advisor and Former Administrator, U.S. Environmental Protection Agency, and include two panels with leaders from industry, government (state and national), and community organizations: one on the decarbonization of the grid and the second on the technologies of geothermal and hydrogen. The closing Clean Energy Engagement Fair will begin with a brief student panel representing groups from across the University, sharing their motivation and approach to involvement. Afterwards, there will be booths and resources providing information about how to get involved in the clean energy space at UConn and in the industry. We are proud of the work that every UConn student undertakes during their education to increase their citizenship and their interest in the social, economic, cultural, and natural environments of the state and beyond.

We hope you can participate. Learn more and register here!