The Pratt & Whitney Additive Manufacturing Center (AMC) at UConn Tech Park has expanded its Department of Defense-related research efforts in recent months with new projects related to submarine and aerospace manufacturing.

The Pratt & Whitney Additive Manufacturing Center (AMC) at UConn Tech Park has expanded its Department of Defense-related research efforts in recent months with new projects related to submarine and aerospace manufacturing.

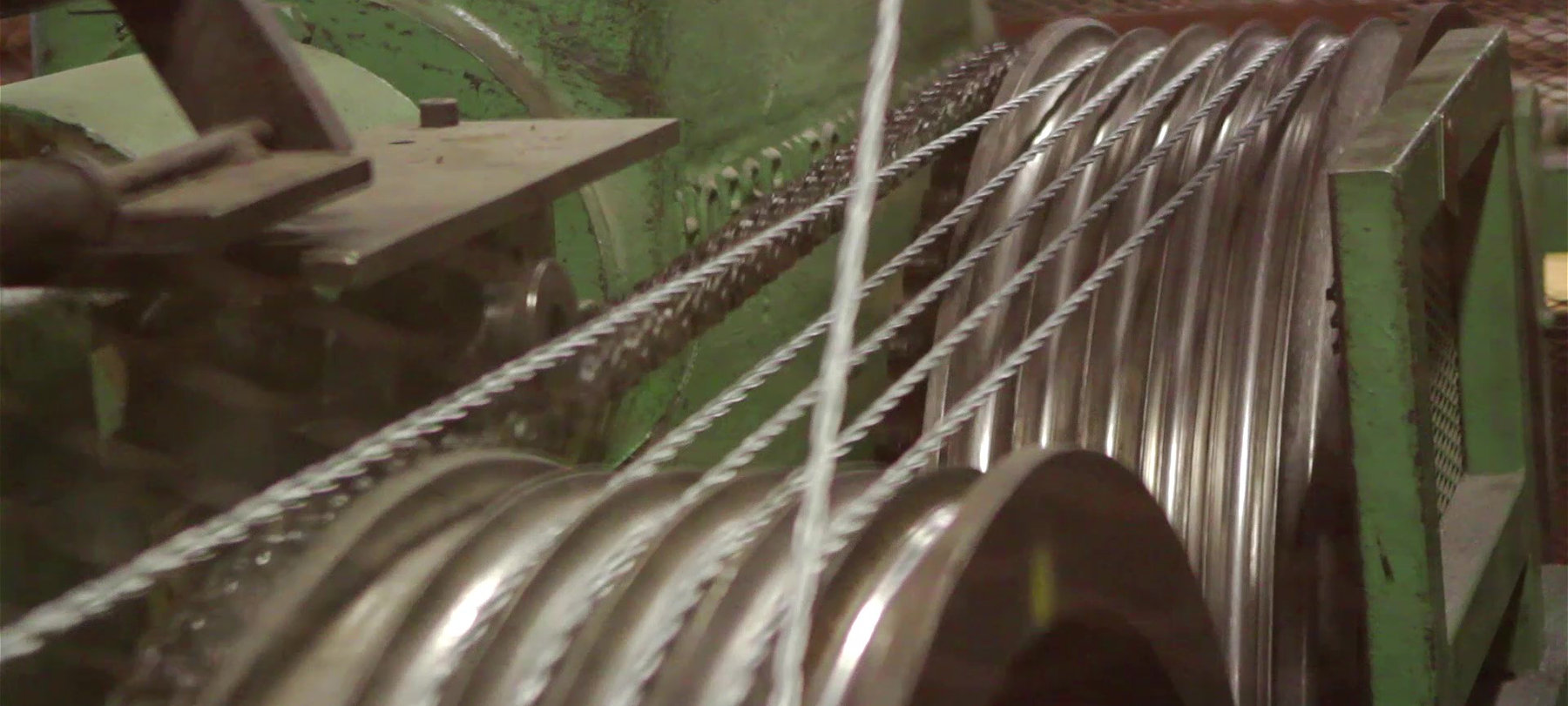

The submarine industrial base hopes to meet the demand for quality submarine parts by focusing increasingly on additive manufacturing. A team of UConn materials science and engineering faculty along with colleagues from the University of Rhode Island recently started a four-year project funded by the National Institute for Undersea Vehicle Technology (NIUVT) to investigate properties of a steel commonly used in submarine production. The team will explore the material characteristics of parts made of this steel using additive manufacturing as compared to traditional manufacturing technologies such as castings and forgings.

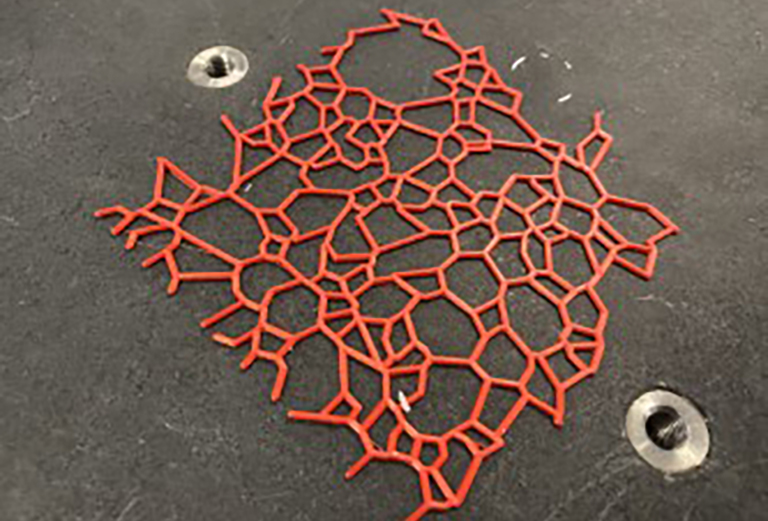

The AMC supports the additive manufacturing aspects of the project that include powder characterization as well as chemical and thermal analysis besides the production of parts. In its newest NIUVT-funded project the AMC will exploit the layer-by-layer manufacturing approach of additive manufacturing to tailor the behavior of bronze materials at specific locations within a part. What is nearly impossible with castings can likely be accomplished with additive manufacturing, for example, to optimize sections of parts for high strength while other regions bear the brunt of energy absorption during service.

The NIUVT additive manufacturing projects and the AMC involvement echo parallel efforts by the Navy to develop an industrial base for additive manufacturing of submarine parts. To this end, the Navy set up an additive manufacturing Center of Excellence in 2022 and in the same context invited researchers from seven US universities to form an academic consortium.

The AMC is part of the consortium and will soon embark on its first project and address the important aspect of metal powder characteristics. Key additive manufacturing technologies use metal powder, and a detailed knowledge of the powder characteristics and flow behavior is needed to advance additive manufacturing to a production level.

Similarly, the Air Force pursues additive manufacturing for some of their current and future systems, particularly in high-temperature applications. Recently, the AMC started a new four-year project sponsored by the Air Force Research Laboratory (AFRL) on refractory metals for additive manufacturing of high-temperature components. Refractory metals such as niobium have melting points well over 4,000 degrees Fahrenheit but have been difficult to produce with conventional manufacturing technologies. The AMC will investigate process conditions during additive manufacturing and their effects on the details of the niobium metals that matter for their use in high-temperature applications.

With the NIUVT, Navy, and Air Force research activities, the AMC supports some of the most critical applications for the nation and in the process prepares students with expertise in state-of-the-art manufacturing technologies.