Amidst the global freshwater crisis, desalination emerges as crucial for meeting the escalating demand for potable and industrial water. Particularly in water-scarce regions, reliance on desalinated water for drinking, cooking and washing continues to grow.

However, reverse osmosis (RO) technologies that are widely employed by the desalination industry are costly and energy-intensive due to inherent characteristics of the RO membranes currently used in the desalination process. To address these challenges, research efforts are currently underway to develop advanced, more durable RO membranes capable of improving energy-efficiency and reducing cost while withstanding the rigors of the desalination process.

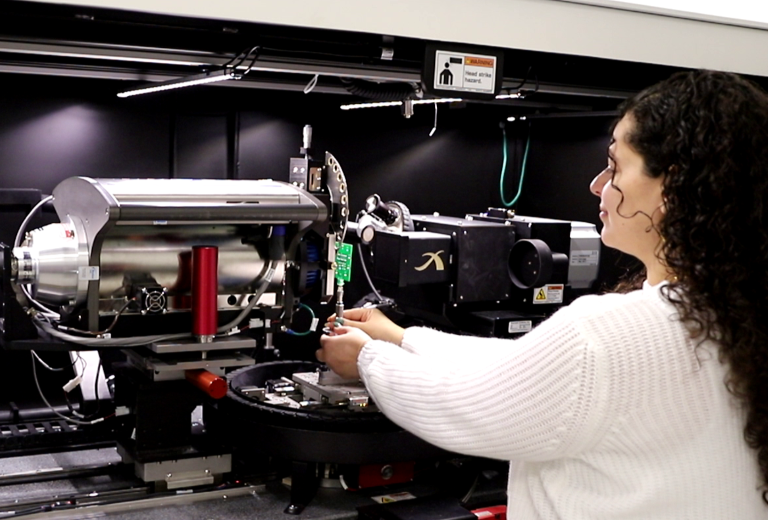

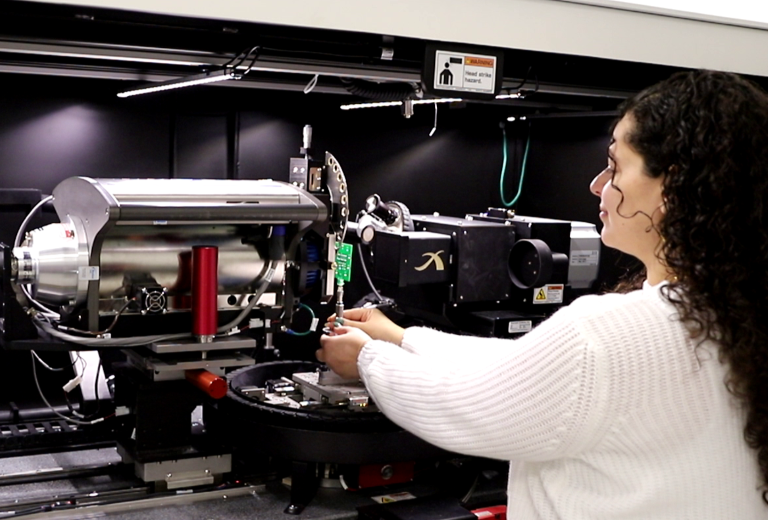

In the recent publication “Characterization of Reverse Osmosis Membranes Under Compaction Utilizing 3D X-ray and 3D FIB Correlative Microscopy”, UConn PhD Graduate Assistant Yara Suleiman and coauthors expand upon their prior research that introduced a novel process for evaluating the performance of RO membranes in water treatment facilities. The innovative approach, utilizing state-of-the-art 3D X-ray and 3D FIB correlative microscopy, offers promising prospects for shaping advancement in membrane technologies that can drive more efficient, less costly desalination, with broader implications for sustainable solutions to the global freshwater crisis.

In the recent publication “Characterization of Reverse Osmosis Membranes Under Compaction Utilizing 3D X-ray and 3D FIB Correlative Microscopy”, UConn PhD Graduate Assistant Yara Suleiman and coauthors expand upon their prior research that introduced a novel process for evaluating the performance of RO membranes in water treatment facilities. The innovative approach, utilizing state-of-the-art 3D X-ray and 3D FIB correlative microscopy, offers promising prospects for shaping advancement in membrane technologies that can drive more efficient, less costly desalination, with broader implications for sustainable solutions to the global freshwater crisis.

Suleiman is a PhD Graduate Assistant at the Reverse Engineering, Fabrication, Inspection and Non-Destructive Analysis (REFINE) lab at the IPB | UConn Tech Park. The article is coauthored with REFINE Center Director Sina Shahbazmohamadi and UCLA’s Professor Eric Hoek and postdoctoral research fellow Jishan Wu.

Citation: Yara Suleiman, Jishan Wu, Eric M V Hoek, Sina Shahbazmohamadi, Characterization of Reverse Osmosis Membranes Under Compaction Utilizing 3D X-ray and 3D FIB Correlative Microscopy, Microscopy and Microanalysis, Volume 29, Issue Supplement_1, 1 August 2023, Pages 144-145, https://doi.org/10.1093/micmic/ozad067.065

In this article, Debasish Mishra, PostDoc (UConn ‘23) and coauthors introduce a novel approach that applies unsupervised Machine Learning to predict tool wear in precision machining accurately. Tested across multiple machines, workpieces, toolings, and cutting settings, the research offers a promising new methodology for improving efficiency and reliability in machining operations by predicting tool replacement decisions.

In this article, Debasish Mishra, PostDoc (UConn ‘23) and coauthors introduce a novel approach that applies unsupervised Machine Learning to predict tool wear in precision machining accurately. Tested across multiple machines, workpieces, toolings, and cutting settings, the research offers a promising new methodology for improving efficiency and reliability in machining operations by predicting tool replacement decisions.

The

The

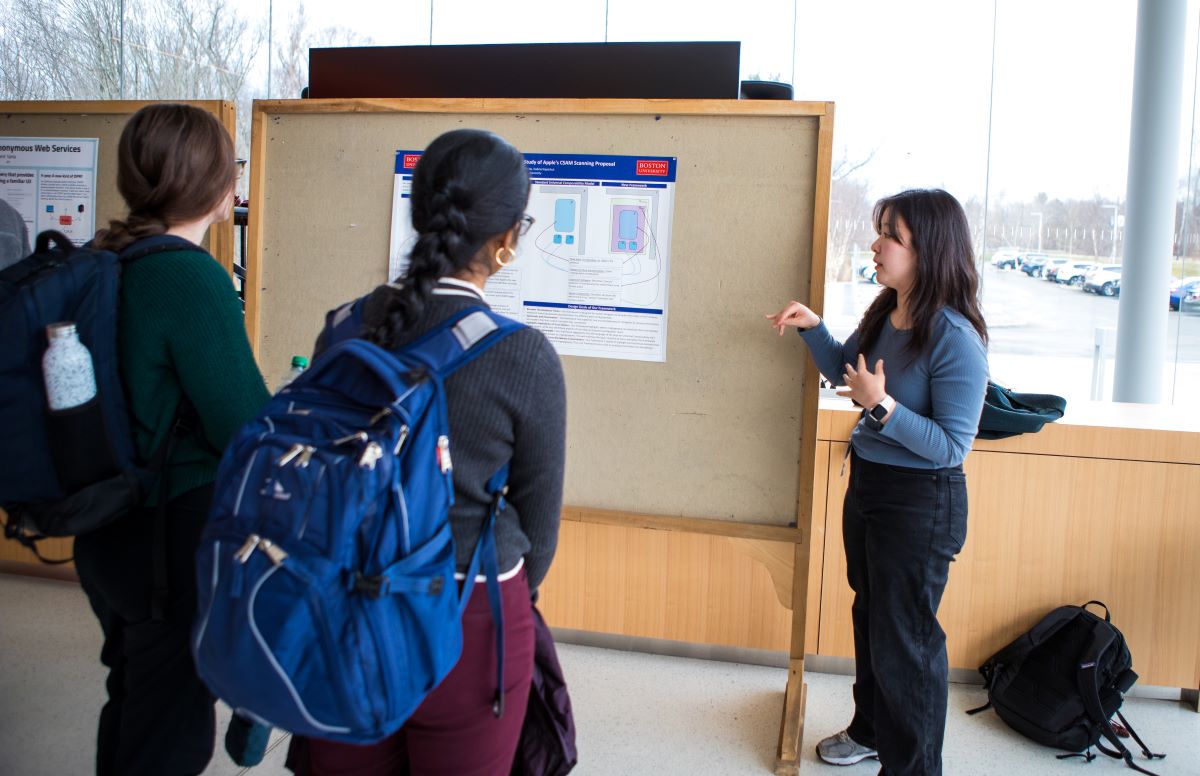

The Center of Clean Energy Engineering (C2E2) hosted its first C2E2 Graduate Student Research Summit in Sustainability on February 16th and 17th at IPB. Organized by graduate students Alanna Gado and Leila Chebbo, the event featured 30 student presentations covering diverse research topics such as cultivated beef, air filter effectiveness, desalination, desulfurization, space exploration, electrolyzers, fuel cells, and membrane applications.

The Center of Clean Energy Engineering (C2E2) hosted its first C2E2 Graduate Student Research Summit in Sustainability on February 16th and 17th at IPB. Organized by graduate students Alanna Gado and Leila Chebbo, the event featured 30 student presentations covering diverse research topics such as cultivated beef, air filter effectiveness, desalination, desulfurization, space exploration, electrolyzers, fuel cells, and membrane applications.

In the recent publication “Characterization of Reverse Osmosis Membranes Under Compaction Utilizing 3D X-ray and 3D FIB Correlative Microscopy”, UConn PhD Graduate Assistant Yara Suleiman and coauthors expand upon their prior research that introduced a novel process for evaluating the performance of RO membranes in water treatment facilities. The innovative approach, utilizing state-of-the-art 3D X-ray and 3D FIB correlative microscopy, offers promising prospects for shaping advancement in membrane technologies that can drive more efficient, less costly desalination, with broader implications for sustainable solutions to the global freshwater crisis.

In the recent publication “Characterization of Reverse Osmosis Membranes Under Compaction Utilizing 3D X-ray and 3D FIB Correlative Microscopy”, UConn PhD Graduate Assistant Yara Suleiman and coauthors expand upon their prior research that introduced a novel process for evaluating the performance of RO membranes in water treatment facilities. The innovative approach, utilizing state-of-the-art 3D X-ray and 3D FIB correlative microscopy, offers promising prospects for shaping advancement in membrane technologies that can drive more efficient, less costly desalination, with broader implications for sustainable solutions to the global freshwater crisis.