Tech Park is delighted to welcome the recently established Nursing and Engineering Innovation Center, co-directed by Tiffany Kelley, UConn School of Nursing and Leila Daneshmandi, UConn College of Engineering. The new center, one of the first of its kind in the nation, focuses on advancing healthcare and promoting workforce and economic development by fostering interdisciplinary collaborations between nursing and engineering.

Patient healthcare greatly benefits from and is influenced by new technologies, but implementing new technology effectively can be a challenge. Engineers are expert problem solvers and builders but may lack clinical insights that are essential for application. Nurses, on the other hand, are ground-floor experts for how a product “should” work and often find themselves improvising solutions for technologies that are complex or less practical.

The Nursing and Engineering Innovation Center aims to bridge this gap by involving nurses and engineers early in the design phase, addressing real-world issues before a product reaches the clinic. User-centered design is a critical first step in overcoming these technology design barriers and holds significant potential to enhance patient care and amplify the impact of healthcare innovations.

The Center will focus its first two to three years on the creation of seed grants for collaborative research among faculty along with joint educational programs for students through Senior Design, coursework, and fellowship programs.

The Center recently announced its NursEng Healthcare Innovation Seed Grant and is currently accepting proposals through November 15, 2023, 5:00 pm. This seed grant was established to promote and support interdisciplinary and innovative research, scholarship, and creative collaborations among faculty from the Schools of Nursing and Engineering that will advance innovation in healthcare technology and have strong potential as a foundation for extramural funding for larger-scale innovation and research activities in the future.

Innovation research, scholarship, and creative collaborations funded by this grant are expected to lead to significant long-term outcomes, such as publications, intellectual property, academic symposia, and future research, scholarship, or collaborations. Click here for more details.

In another initiative, the Center launched the NursEng Innovation Fellowship in April that teams up nursing and engineering undergraduates and empowers them to tackle unmet needs in equitable healthcare quality and to design innovative healthcare technology solutions.

Daneshmandi, a seasoned entrepreneur, explains, “this new program is designed to foster creativity, collaboration, and user-driven innovation and entrepreneurial thinking in healthcare.”

Students are selected for the Fellowship through a proposal process to collaborate as part of an interdisciplinary team to address a healthcare challenge in need of a technological solution. Throughout the academic year, Fellows are trained in user-driven innovation, prototype development, and entrepreneurial skills. Students also benefit from mentoring sessions and access to prototyping centers and receive up to $1750 in seed funding to support prototype development. At the culmination of the Fellowship year, each student team will present their project achievements and upon successful completion of the program, Fellows will receive a certificate of completion. This initiative is currently funded by an awarded Courses and Programs grant from VentureWell.

The Nursing and Engineering Innovation Center’s longer-term strategy is to expand its scope to create a shared state-of-the-art research and teaching facility, which will require major University, state, federal, or donor investment.

Kelley is enthusiastic about the potential offered by the new Center, saying, “By partnering our students and workforce in the nursing and engineering fields and advancing their education with the appropriate knowledge, skills, and attitudes toward innovative behaviors and culture, we hold the potential to drive significant positive change in the profession of nursing and health care at large.”

Visit the Nursing and Engineering Innovation Center web site to learn more about the Center, meet this year’s seven Fellows, and find out about other opportunities at the Nursing and Engineering Innovation Center.

Tiffany Kelley, Ph.D., MBA, RN-BC, is Visiting Professor and Director of the UConn School of Nursing’s Healthcare Innovation Online Graduate Certificate Program. Leila Daneshmandi, Ph.D., is Assistant Professor in Residence in Innovation and Entrepreneurship and Director of the entrepreneurship Hub (eHub) in the UConn School of Engineering.

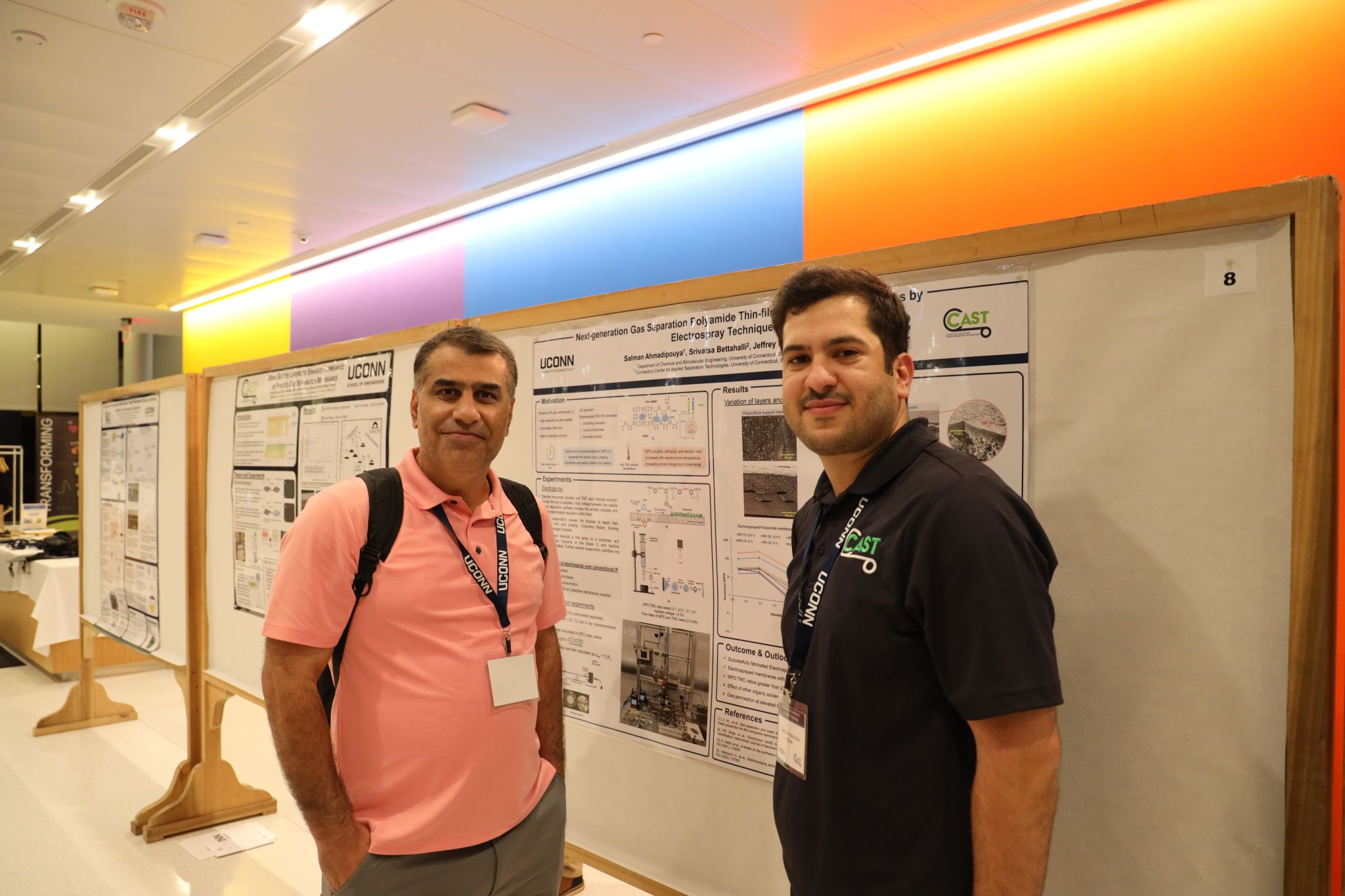

The Center of Clean Energy Engineering (C2E2) hosted its first C2E2 Graduate Student Research Summit in Sustainability on February 16th and 17th at IPB. Organized by graduate students Alanna Gado and Leila Chebbo, the event featured 30 student presentations covering diverse research topics such as cultivated beef, air filter effectiveness, desalination, desulfurization, space exploration, electrolyzers, fuel cells, and membrane applications.

The Center of Clean Energy Engineering (C2E2) hosted its first C2E2 Graduate Student Research Summit in Sustainability on February 16th and 17th at IPB. Organized by graduate students Alanna Gado and Leila Chebbo, the event featured 30 student presentations covering diverse research topics such as cultivated beef, air filter effectiveness, desalination, desulfurization, space exploration, electrolyzers, fuel cells, and membrane applications.

The Annual Eversource Energy Center (EEC) Workshop convened on February 9th at the Innovation Partnership Building and attracted over 80 participants from industry, government, and academia, including top New England utility companies Eversource, Avangrid, ConEdison, and National Grid, alongside others such as PECO (Exelon) and Hydro Quebec. Notable attendees also included ISO-NE, with responsibility for ensuring reliability and overseeing electricity markets across all of New England. Keynote speaker David Howard, Director of Grid Components at the U.S. Department of Energy Office of Electricity, addressed the gathering.

The Annual Eversource Energy Center (EEC) Workshop convened on February 9th at the Innovation Partnership Building and attracted over 80 participants from industry, government, and academia, including top New England utility companies Eversource, Avangrid, ConEdison, and National Grid, alongside others such as PECO (Exelon) and Hydro Quebec. Notable attendees also included ISO-NE, with responsibility for ensuring reliability and overseeing electricity markets across all of New England. Keynote speaker David Howard, Director of Grid Components at the U.S. Department of Energy Office of Electricity, addressed the gathering.

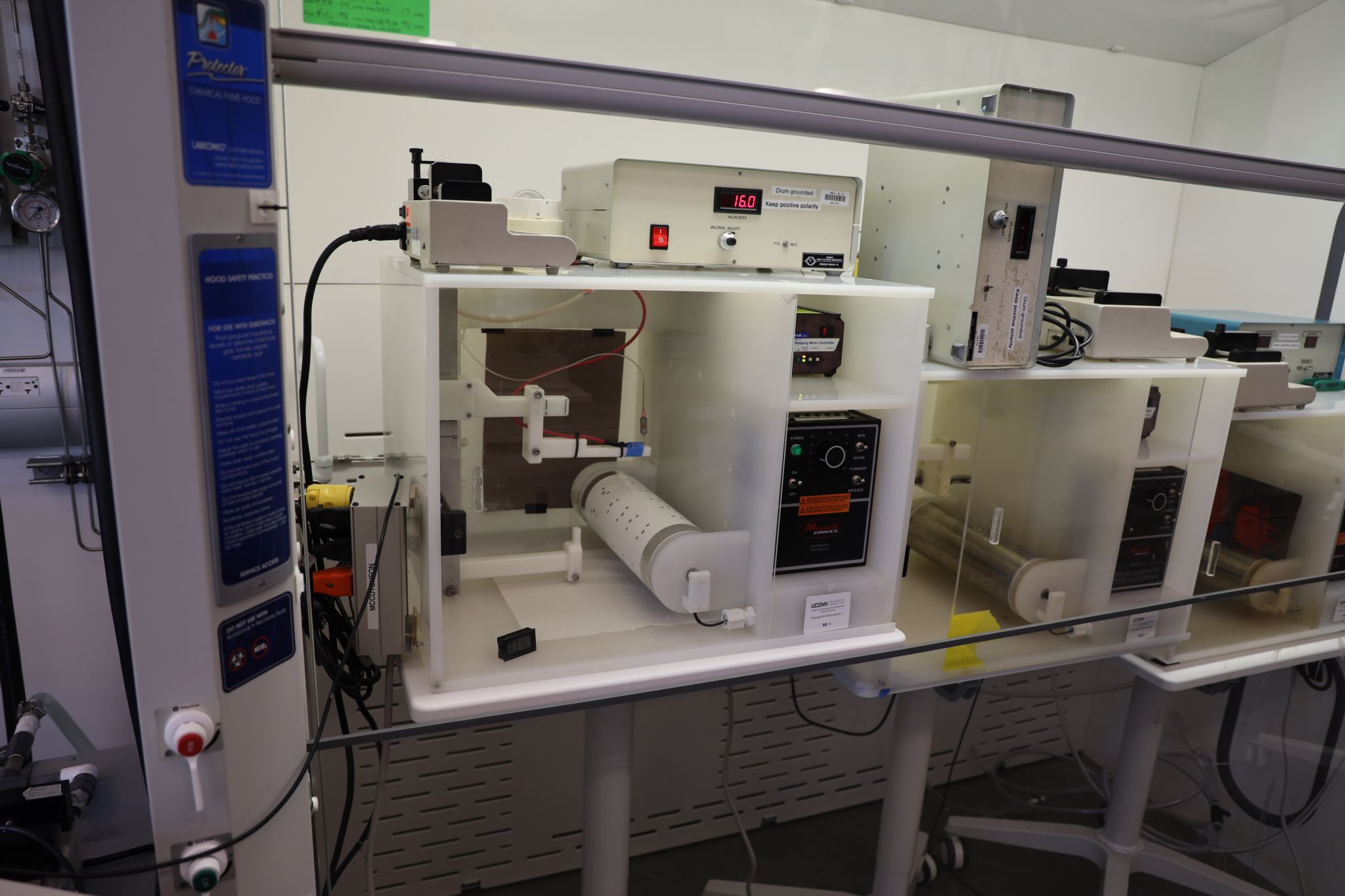

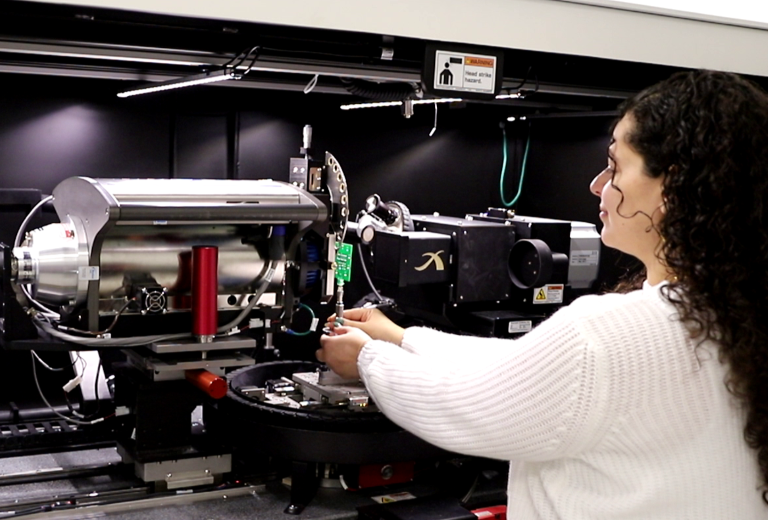

In the recent publication “Characterization of Reverse Osmosis Membranes Under Compaction Utilizing 3D X-ray and 3D FIB Correlative Microscopy”, UConn PhD Graduate Assistant Yara Suleiman and coauthors expand upon their prior research that introduced a novel process for evaluating the performance of RO membranes in water treatment facilities. The innovative approach, utilizing state-of-the-art 3D X-ray and 3D FIB correlative microscopy, offers promising prospects for shaping advancement in membrane technologies that can drive more efficient, less costly desalination, with broader implications for sustainable solutions to the global freshwater crisis.

In the recent publication “Characterization of Reverse Osmosis Membranes Under Compaction Utilizing 3D X-ray and 3D FIB Correlative Microscopy”, UConn PhD Graduate Assistant Yara Suleiman and coauthors expand upon their prior research that introduced a novel process for evaluating the performance of RO membranes in water treatment facilities. The innovative approach, utilizing state-of-the-art 3D X-ray and 3D FIB correlative microscopy, offers promising prospects for shaping advancement in membrane technologies that can drive more efficient, less costly desalination, with broader implications for sustainable solutions to the global freshwater crisis.