IPB at UConn Tech Park

Nanoparticle-Stabilized Emulsions and Foams

PUBLICATION

Shing-Yun Chang, Sahil R. Vora, Charles D. Young, Abhishek Shetty & Anson W. K. Ma. Viscoelasticity of a carbon nanotube-laden air–water interface. Eur. Phys. J. E 47, 18 (2024). https://doi.org/10.1140/epje/s10189-024-00411-0

Emulsions and foams are ubiquitously found in pharmaceutical, agricultural, personal care, and food products. Although it has been known for more than a century that small, nanoscale particles may be added to stabilize these products and increase their shelf-life, accurately capturing the behavior of these particles remains extremely challenging. In this article, UConn researchers critically compare two state-of-the-art experimental methods for studying particles at an interface, laying the foundation for predicting and improving the stability and performance of a wide range of commercial products.

Click here to read the full article.

Predicting Tool Wear in Precision Machining through Unsupervised Machine Learning

PUBLICATION

Debasish Mishra, Utsav Awasthi, Krishna R. Pattipati & George M. Bollas. Tool wear classification in precision machining using distance metrics and unsupervised machine learning. J Intell Manuf (2023). https://doi.org/10.1007/s10845-023-02239-5

In this article, Debasish Mishra, PostDoc (UConn ‘23) and coauthors introduce a novel approach that applies unsupervised Machine Learning to predict tool wear in precision machining accurately. Tested across multiple machines, workpieces, toolings, and cutting settings, the research offers a promising new methodology for improving efficiency and reliability in machining operations by predicting tool replacement decisions.

In this article, Debasish Mishra, PostDoc (UConn ‘23) and coauthors introduce a novel approach that applies unsupervised Machine Learning to predict tool wear in precision machining accurately. Tested across multiple machines, workpieces, toolings, and cutting settings, the research offers a promising new methodology for improving efficiency and reliability in machining operations by predicting tool replacement decisions.

This research was supported by the Air Force Research Laboratory, Materials and Manufacturing Directorate [FA8650-20-C-5206].

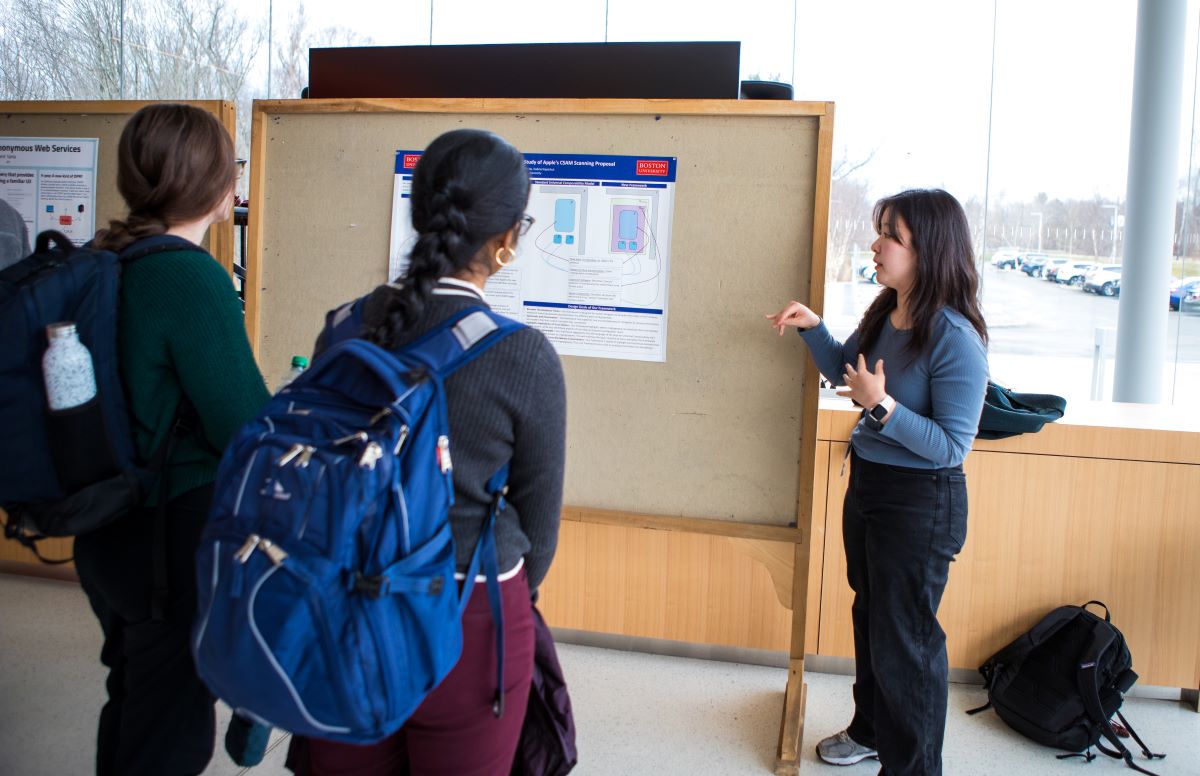

New England Security Day 2024

On March 15th, the Innovation Partnership Building hosted New England Security Day 2024 (NESD), featuring cutting-edge cybersecurity research by experts from academic and professional backgrounds. Participants included industry professionals and academic institutions such as Boston University, Brown, Harvard, UMass, MIT, Northeastern, WPI, and Yale. Attendees had the opportunity to learn about the latest advancements in technology and network for potential collaboration and employment prospects. The conference welcomed a diverse audience of professionals, academics, and graduate and undergraduate students interested in cybersecurity, regardless of their familiarity with advanced concepts like fuzzers, machine learning methods for intrusion detection, or efficient post-quantum cryptography.

Visit the NESD 2024 web page for additional information and to view the NESD 2024 video, complete event program and additional photos.

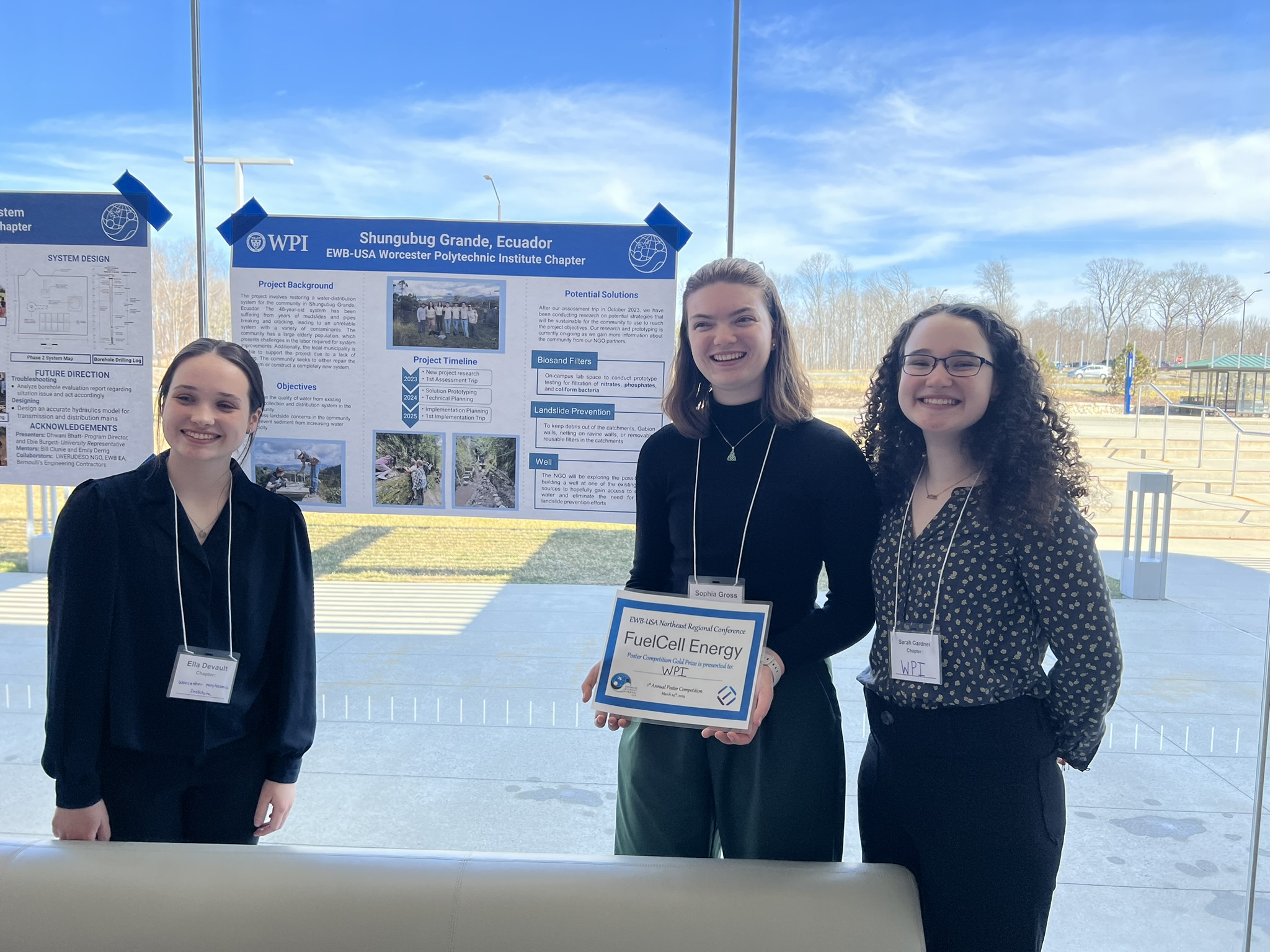

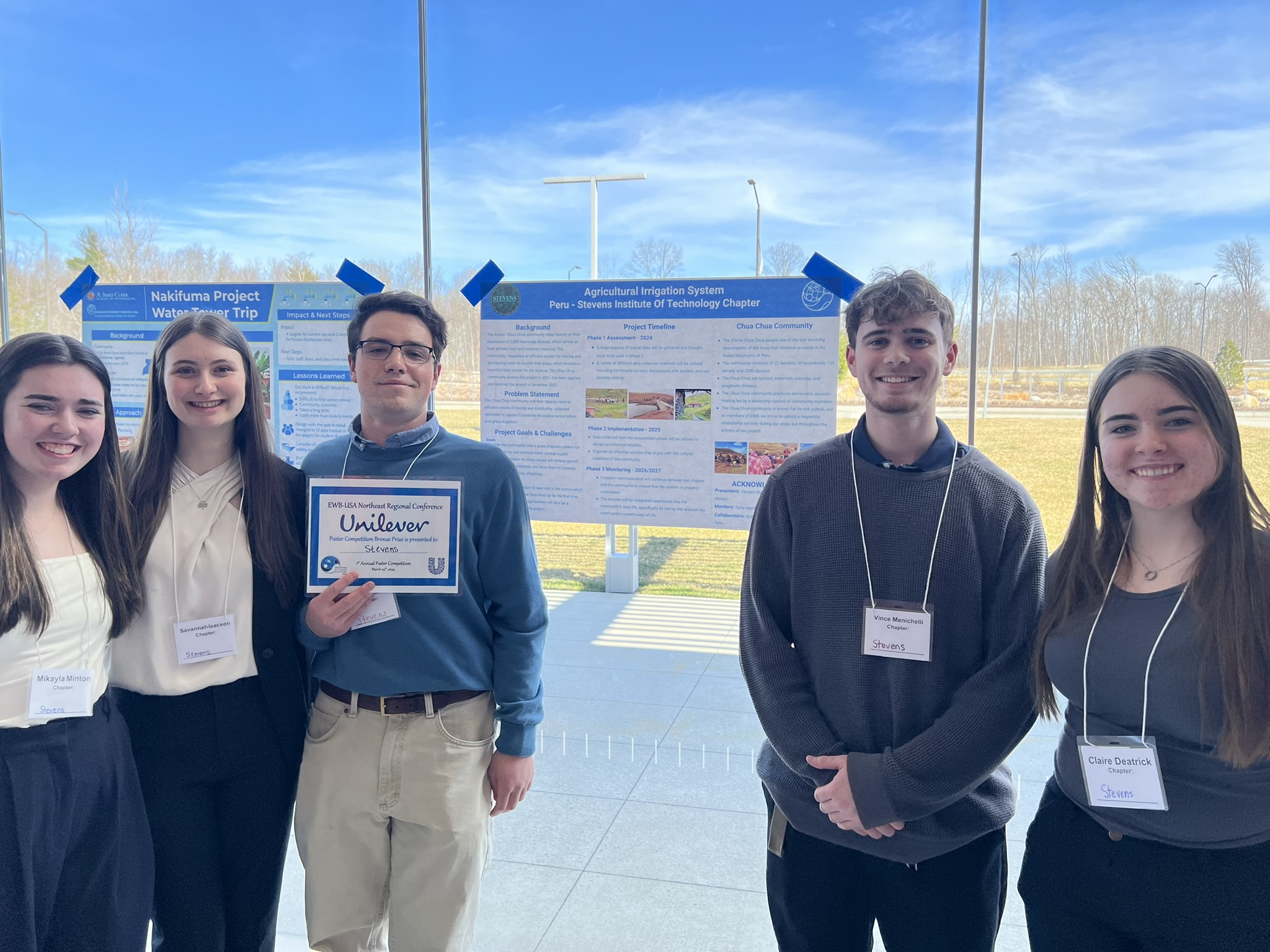

Engineering for Global Impact: Highlights from the Engineers Without Borders 2024 Northeast Regional Conference

The Engineers Without Borders (EWB) 2024 Northeast Regional Conference, hosted at UConn’s Innovation Partnership Building in March, brought together over 100 engineering students, professionals, and faculty advisors. Participants engaged in technical sessions, workshops, and professional development activities. EWB-USA, a nonprofit organization, supports community-driven engineering projects globally, with 155 chapters nationwide, including 42 in the northeast.

Attendees included special guests hydrogeologist Nadia Glucksberg and geologist-environmental scientist Helena Hollauer, along with Community Engineering Corps, an EWB partner organization that helps U.S. communities lacking engineering services. A full-day poster session showcased attendees’ recent projects, and EWB-UConn discussed their sanitation and sustainability initiatives in Peru and Kenya.

“The conference brought together students and professionals that want to use engineering to make the world a better place for more people,” says Jeffrey McCutcheon, Centennial Professor in the Chemical and Biomolecular Engineering Department. “It’s a very important change in the way that engineering is perceived, and I believe better addresses the interest of our next generation of engineers.”

EWB-UConn President Brian Machado’25 (ENG) praised the turnout and camaraderie among chapters, reflecting a shared commitment to engineering for global betterment.

Read the full article here.

Pratt & Whitney Additive Manufacturing Center Expands Defense Research

The Pratt & Whitney Additive Manufacturing Center (AMC) at UConn Tech Park has expanded its Department of Defense-related research efforts in recent months with new projects related to submarine and aerospace manufacturing.

The Pratt & Whitney Additive Manufacturing Center (AMC) at UConn Tech Park has expanded its Department of Defense-related research efforts in recent months with new projects related to submarine and aerospace manufacturing.

The submarine industrial base hopes to meet the demand for quality submarine parts by focusing increasingly on additive manufacturing. A team of UConn materials science and engineering faculty along with colleagues from the University of Rhode Island recently started a four-year project funded by the National Institute for Undersea Vehicle Technology (NIUVT) to investigate properties of a steel commonly used in submarine production. The team will explore the material characteristics of parts made of this steel using additive manufacturing as compared to traditional manufacturing technologies such as castings and forgings.

The AMC supports the additive manufacturing aspects of the project that include powder characterization as well as chemical and thermal analysis besides the production of parts. In its newest NIUVT-funded project the AMC will exploit the layer-by-layer manufacturing approach of additive manufacturing to tailor the behavior of bronze materials at specific locations within a part. What is nearly impossible with castings can likely be accomplished with additive manufacturing, for example, to optimize sections of parts for high strength while other regions bear the brunt of energy absorption during service.

The NIUVT additive manufacturing projects and the AMC involvement echo parallel efforts by the Navy to develop an industrial base for additive manufacturing of submarine parts. To this end, the Navy set up an additive manufacturing Center of Excellence in 2022 and in the same context invited researchers from seven US universities to form an academic consortium.

The AMC is part of the consortium and will soon embark on its first project and address the important aspect of metal powder characteristics. Key additive manufacturing technologies use metal powder, and a detailed knowledge of the powder characteristics and flow behavior is needed to advance additive manufacturing to a production level.

Similarly, the Air Force pursues additive manufacturing for some of their current and future systems, particularly in high-temperature applications. Recently, the AMC started a new four-year project sponsored by the Air Force Research Laboratory (AFRL) on refractory metals for additive manufacturing of high-temperature components. Refractory metals such as niobium have melting points well over 4,000 degrees Fahrenheit but have been difficult to produce with conventional manufacturing technologies. The AMC will investigate process conditions during additive manufacturing and their effects on the details of the niobium metals that matter for their use in high-temperature applications.

With the NIUVT, Navy, and Air Force research activities, the AMC supports some of the most critical applications for the nation and in the process prepares students with expertise in state-of-the-art manufacturing technologies.

New Regional Centers Focus on Electrical Grid Cybersecurity

UConn Leading Federally Backed Regional Initiative to Defend Electric Grid from Cyberattack

UConn Awarded $4.5M DOE Grant to Benefit Grid Reliability for Transmission and Distribution Systems

NIUVT-UConn Welcome Congressman Joe Courtney and Mr. Paul Myler, Embassy of Australia Deputy, for AUKUS Partnership Briefing

On Thursday March 14th, the National Institute for Undersea Vehicle Technology (NIUVT), together with the UConn College of Engineering, welcomed Congressman Joseph Courtney and Mr. Paul Myler, Deputy Head of Mission for the Embassy of Australia Washington DC, to the Innovation Partnership Building. Congressman Courtney and Mr. Meyer were briefed on UConn NIUVT leadership’s recent visit to Australia, where they engaged with government and academia regarding mutual interests and opportunities to partner in research and workforce development opportunities available because of AUKUS, the trilateral partnership between the United States, Australia, and the United Kingdom.

On Thursday March 14th, the National Institute for Undersea Vehicle Technology (NIUVT), together with the UConn College of Engineering, welcomed Congressman Joseph Courtney and Mr. Paul Myler, Deputy Head of Mission for the Embassy of Australia Washington DC, to the Innovation Partnership Building. Congressman Courtney and Mr. Meyer were briefed on UConn NIUVT leadership’s recent visit to Australia, where they engaged with government and academia regarding mutual interests and opportunities to partner in research and workforce development opportunities available because of AUKUS, the trilateral partnership between the United States, Australia, and the United Kingdom.

|

|