R&D

UConn Awarded $4.5M DOE Grant to Benefit Grid Reliability for Transmission and Distribution Systems

Forecasting Wind Energy

C2E2 Graduate Student Research Summit in Sustainability

The Center of Clean Energy Engineering (C2E2) hosted its first C2E2 Graduate Student Research Summit in Sustainability on February 16th and 17th at IPB. Organized by graduate students Alanna Gado and Leila Chebbo, the event featured 30 student presentations covering diverse research topics such as cultivated beef, air filter effectiveness, desalination, desulfurization, space exploration, electrolyzers, fuel cells, and membrane applications.

The Center of Clean Energy Engineering (C2E2) hosted its first C2E2 Graduate Student Research Summit in Sustainability on February 16th and 17th at IPB. Organized by graduate students Alanna Gado and Leila Chebbo, the event featured 30 student presentations covering diverse research topics such as cultivated beef, air filter effectiveness, desalination, desulfurization, space exploration, electrolyzers, fuel cells, and membrane applications.

The summit offered a venue for doctoral candidates to share their ongoing research and engage in discussions about sustainability challenges. Participants had the opportunity to refine their presentation skills and receive feedback from both peers and faculty members. Networking sessions facilitated connections among students and others within the C2E2 community.

Presentations were evaluated by the audience, with awards given in three categories. Leila Chebbo took first place, followed by Christabel Adjah-Tetteh in second, and Alanna Gado, Hasnain Nisar, Yasmin Bimbatti, and Ben Cohen sharing third place. Additionally, honorable mentions were awarded to Elena Ford, Christopher Hawxhurst, and Hasan Nikkah.

The summit demonstrated the students’ commitment to advancing clean energy technologies and tackling sustainability challenges, and underscores C2E2’s commitment to fostering the development of future researchers and innovators in the field.

Student Advisors

| Christabel Adjah-Tetteh | Professor Xiao-Dong Zhou, Director of C2E2 Chemical Engineering |

| Yasmin Bimbatti | Professor Jeffrey McCutcheon Chemical and Biomolecular Engineering |

| Leila Chebbo | Associate Professor Ali Bazzi Electrical Computing and Engineering |

| Ben Cohen | Professor George Bollas & Assistant Professor Burcu Beykal Chemical and Biomolecular Engineering |

| Elena Ford | Assistant Research Professor Naba Karan C2E2 |

| Alanna Gado | Radenka Maric President | University of Connecticut Board of Trustees Distinguished Professor |

| Christopher Hawxhurst | Professor Lesli Shor Chemical and Biomolecular Engineering |

| Hasan Nikkah | Associate Professor Burcu Beykal Chemical and Biomolecular Engineering |

| Hasnain Nisar | Assistant Professor Ali Bazzi Electrical Computing and Engineering |

Annual Eversource Energy Center Workshop 2024

The Annual Eversource Energy Center (EEC) Workshop convened on February 9th at the Innovation Partnership Building and attracted over 80 participants from industry, government, and academia, including top New England utility companies Eversource, Avangrid, ConEdison, and National Grid, alongside others such as PECO (Exelon) and Hydro Quebec. Notable attendees also included ISO-NE, with responsibility for ensuring reliability and overseeing electricity markets across all of New England. Keynote speaker David Howard, Director of Grid Components at the U.S. Department of Energy Office of Electricity, addressed the gathering.

The Annual Eversource Energy Center (EEC) Workshop convened on February 9th at the Innovation Partnership Building and attracted over 80 participants from industry, government, and academia, including top New England utility companies Eversource, Avangrid, ConEdison, and National Grid, alongside others such as PECO (Exelon) and Hydro Quebec. Notable attendees also included ISO-NE, with responsibility for ensuring reliability and overseeing electricity markets across all of New England. Keynote speaker David Howard, Director of Grid Components at the U.S. Department of Energy Office of Electricity, addressed the gathering.

The workshop centered on EEC’s five research pillars, encompassing grid resilience and reliability, renewable energy, cyber-physical system security, and workforce training and outreach. The morning kicked off with presentations from UConn faculty showcasing nineteen ongoing funded projects spanning these topics, sharing progress with industry stakeholders, advisory board members, and colleagues.

Afternoon breakout groups provided the opportunity for in-depth discussion of the individual projects presented during the morning session. Researchers received valuable feedback on industry priorities and needs, discussed next steps, and shared insights on potential new research and funding opportunities.

According to Assistant Professor Diego Cerrai, Associate Director for EEC, “This was a fantastic day where we were able to network, reconnect, and exchange ideas.” Assistant Professor Xinxuan Zhang, EEC Center Manager, adds, “The afternoon session I participated in was extremely valuable for informing new ideas for my research. It was very inspiring to see the enthusiasm and engagement of my colleagues and industry partners.”

This robust framework is central to EEC’s continued success. EEC Center Director and UConn Tech Park Executive Director Emmanouil Anagnostou was delighted with the outcome. “The annual workshop is vital to the Eversource Energy Center’s power grid resilience and clean energy. It continues to build upon ongoing research and provides a critical foundation that enhances our prospects for future federal funding on climate resilience, smart grid, and sustainability as well as collaboration and co-sponsorships with industry.”

Eversource Energy Center Mission Statement and Pillars

Mission

To be the foremost energy utility-academia partnership advancing leading-edge interdisciplinary research and technology assuring reliable power during extreme weather and security events.

Pillars

To fulfill our mission, our center will focus the new EVERSOURCE-UConn partnership research activities over the next five years under the following five pillars:

1. Grid Resilience in a Warming Climate

2. Grid Reliability in a Changing Demand Environment

3. Renewable Energy Integration

4. Cyber-Physical System Security

5. Workforce training, outreach, and policy

About Eversource Energy Center

The Eversource Energy Center, a partnership between UConn and Eversource utility company, addresses resilience challenges in the energy sector, particularly regarding extreme weather, climate change, and clean power infrastructure. Housed at UConn’s Innovation Partnership Building, the Center leverages university resources to innovate and develop solutions for weather-related risks and security events. Supported by funding from various sources, including utilities, industry, and federal entities, the Center serves as a hub for interdisciplinary research, teaching, and workforce development. Emphasizing both technological advancement and people development, the Center supports student programs and diversity initiatives. EEC is committed to active collaborations driving innovation in storm preparedness, grid resilience, and modernization, inviting further participation in shaping the future grid.

Ripple Effect: Reverse Osmosis Technology – Implications for Reshaping the Clean Water Landscape

Amidst the global freshwater crisis, desalination emerges as crucial for meeting the escalating demand for potable and industrial water. Particularly in water-scarce regions, reliance on desalinated water for drinking, cooking and washing continues to grow.

However, reverse osmosis (RO) technologies that are widely employed by the desalination industry are costly and energy-intensive due to inherent characteristics of the RO membranes currently used in the desalination process. To address these challenges, research efforts are currently underway to develop advanced, more durable RO membranes capable of improving energy-efficiency and reducing cost while withstanding the rigors of the desalination process.

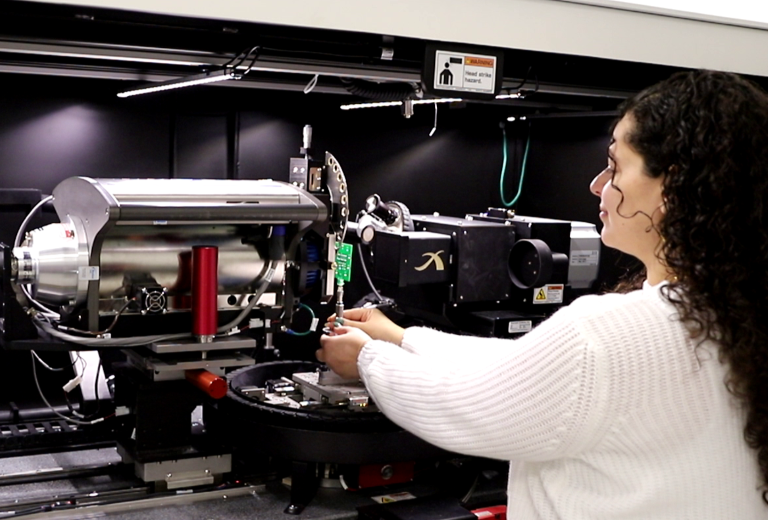

In the recent publication “Characterization of Reverse Osmosis Membranes Under Compaction Utilizing 3D X-ray and 3D FIB Correlative Microscopy”, UConn PhD Graduate Assistant Yara Suleiman and coauthors expand upon their prior research that introduced a novel process for evaluating the performance of RO membranes in water treatment facilities. The innovative approach, utilizing state-of-the-art 3D X-ray and 3D FIB correlative microscopy, offers promising prospects for shaping advancement in membrane technologies that can drive more efficient, less costly desalination, with broader implications for sustainable solutions to the global freshwater crisis.

In the recent publication “Characterization of Reverse Osmosis Membranes Under Compaction Utilizing 3D X-ray and 3D FIB Correlative Microscopy”, UConn PhD Graduate Assistant Yara Suleiman and coauthors expand upon their prior research that introduced a novel process for evaluating the performance of RO membranes in water treatment facilities. The innovative approach, utilizing state-of-the-art 3D X-ray and 3D FIB correlative microscopy, offers promising prospects for shaping advancement in membrane technologies that can drive more efficient, less costly desalination, with broader implications for sustainable solutions to the global freshwater crisis.

Suleiman is a PhD Graduate Assistant at the Reverse Engineering, Fabrication, Inspection and Non-Destructive Analysis (REFINE) lab at the IPB | UConn Tech Park. The article is coauthored with REFINE Center Director Sina Shahbazmohamadi and UCLA’s Professor Eric Hoek and postdoctoral research fellow Jishan Wu.

Citation: Yara Suleiman, Jishan Wu, Eric M V Hoek, Sina Shahbazmohamadi, Characterization of Reverse Osmosis Membranes Under Compaction Utilizing 3D X-ray and 3D FIB Correlative Microscopy, Microscopy and Microanalysis, Volume 29, Issue Supplement_1, 1 August 2023, Pages 144-145, https://doi.org/10.1093/micmic/ozad067.065

Registration Open for New England Security Day

UConn will host the New England Security Day on March 15, 2024 at the Innovation Partnership Building | UConn Tech Park. This event showcases cutting-edge research in all areas of cybersecurity from academics and professionals. The audience is a mix of students (undergraduate and graduate) and working researchers. It represents an opportunity to learn about state-of-the-art and recruit phenomenal students from universities across New England. The program committee creating the schedule has participants from Boston University, Brown, UConn, Harvard, UMass, MIT, Northeastern, WPI, and Yale. We encourage attendance and participation from industry. Talks will be accessible to a general audience in cybersecurity so don’t worry if you’re behind on the latest fuzzer, ML methods for intrusion detection, or efficient post-quantum cryptography.

Please register here. If you would like to be more involved please contact Jessica Guilbeault jessica.guilbeault@uconn.edu and Benjamin Fuller Benjamin.fuller@uconn.edu.

Moving Beyond Implications: Research into Policy Inaugural Conference

UConn Tech Park responded to a call for researchers to shape policies that optimize benefit to Connecticut’s communities, environment, and economy. Interim Executive Director Emmanouil Anagnostou and Professor George Bollas, along with other researchers and academicians, participated in the inaugural “Moving Beyond Implications: Research into Policy” conference at the State Capitol. This event fosters collaboration between policymakers and researchers, promoting evidence-based policymaking in the state. Anagnostou and Bollas presented topics related to the impact of extreme rainfall on water infrastructure and non-carbon-based fuels, respectively, contributing to the dynamic discussion on how scientists can inform future policy decisions for impactful results.

Check out the UConn Today article, “Conference to Unite Legislators and Scientists in Joint Effort to Strengthen Connecticut” for additional details on the conference’s objectives and background.

Co-organizers State Rep. Jaime Foster and Kerri Raissian provide post-conference commentary in the CT Mirror article, “For progress, put Connecticut lawmakers and researchers in the same room.”

CBIA BizCast: UConn Tech Park Drives Innovation » CBIA

“This isn’t just a good resource. It’s an unbelievable resource,” says Mike DiDonato, business development manager at UConn Tech Park – Innovation Partnership Building. DiDonato joined the CBIA BizCast recently to talk about how UConn Tech Park is helping businesses in Connecticut.

Leveraging Active Machine Learning to Optimize 3D Printing Autonomously

Inkjet printing has evolved from a graphics and marking technology to a broader variety of additive manufacturing and 3D printing processes for electronic, optical, pharmaceutical, and biological applications. The success of adopting inkjet technology for these newer applications is contingent on whether the ink materials can be consistently and reliably jetted by the print systems. Currently, each printer-and-ink combination requires calibration by trial and error, which consumes a considerable amount of time and materials. IPB researcher, Prof. Anson Ma, Site Director of SHAP3D, teamed up with UConn machine learning expert, Prof. Qian Yang, to demonstrate a new concept of “autonomous 3D printing”, leveraging an active machine learning method they developed to efficiently create a jettability diagram that predicts the best conditions for jetting an ink from a printhead.

Briefly, a camera is used to image the printhead and capture the behavior of ink jetted from a printhead. Starting with a few randomly chosen conditions, a machine learning algorithm predicts the optimal jetting conditions and then “cleverly decides” on the next set of experiments that can further improve prediction accuracy. After performing those experiments, the algorithm analyzes the newly acquired images, updates the prediction for the desired jetting conditions, and iteratively selects the next experiments, continuing autonomously until a small experimental budget is reached. This approach has achieved a prediction accuracy of more than 95% while considerably reducing the number of experiments required by 80% compared to a typical grid-search approach. This novel approach is especially powerful for optimizing complex print systems with many tunable process parameters.

This work was recently published in the journal 3D Printing and Additive Manufacturing (http://doi.org/10.1089/3dp.2023.0023) and led to a pending patent application (WO 2023/2788542).